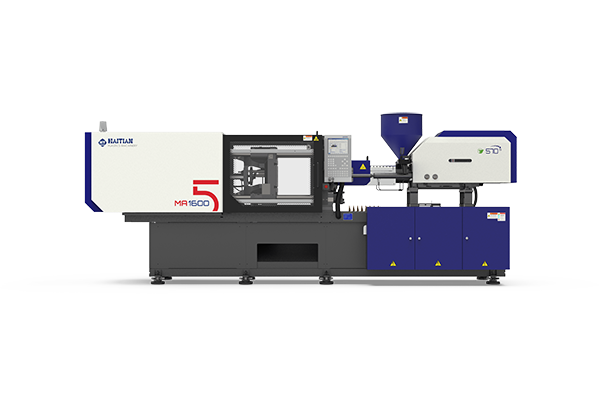

Energy-saving, efficient, and intelligent: Based on fifth-generation technology and inheriting the excellent genes of the world's best-selling servo-hydraulic energy-saving injection molding technology, MARS 5 has been launched. As one of our advanced hydraulic injection machines, MARS 5 delivers optimized performance in every aspect from injection molding to plasticizing and mold clamping structures ensuring significant breakthroughs and enhancements across the system. Its hardware configuration continues to evolve, offering new appearance upgrades and setting industry benchmarks in performance and quality, while maintaining exceptional adaptability for future manufacturing demands. Equipped with multiple intelligent technologies, it fully meets customers’ personalized and flexible production requirements while significantly improving overall efficiency. In addition, the newly developed electric charger works seamlessly with the latest energy-saving and information technologies to make the injection molding process more energy-efficient and smarter. This innovation also complements our portfolio of all-electric injection machines, creating a new intelligent injection molding ecosystem that supports high productivity and sustainable production.

The world's best-selling injection moulding machine

Interactive with open integration

Smart features "from Haitian" as standard

New high-drive, energy-saving servo system from "Haitian"

20-40% Electric pre-moulding with a higher energy saving rate

The automotive sector is multifaceted and growing rapidly. Our approach Cost-effective system solutions for flexible and fully automated intelligent production lines.

The consumer goods market is the mass market for plastic products and is more competitive than others. Sometimes, despite high quality requirements, standardised practices in production.

Our everyday life is rich in technical systems such as mobile phones, tablets, computers or memory cards and connectors. New slim designs, new surfaces, innovative functions and short product cycles require competitive solutions.

The large dimensions and volumes of the parts quickly shift the focus to material consumption and processing. If you want to survive in the face of tough competition, this requires well thought-out, cost-effective production solutions.

MARS 5 is equipped with flexible open integration functions, providing enhanced connectivity and intelligent control. The entire series is equipped with the "Go Factory 2.0" digital intelligent management software to best meet your operational needs. As a next-generation plastic injection machine, MARS 5 ensures intelligent production processes that are automated, transparent, and efficient. Designed as a fully integrated injection molding machine solution, it enables customers to achieve smarter manufacturing from a single source.

600 - 12,000 kN13,000 - 33,000 kN

We will do our best to get back to you as soon as possible after we receive your form.