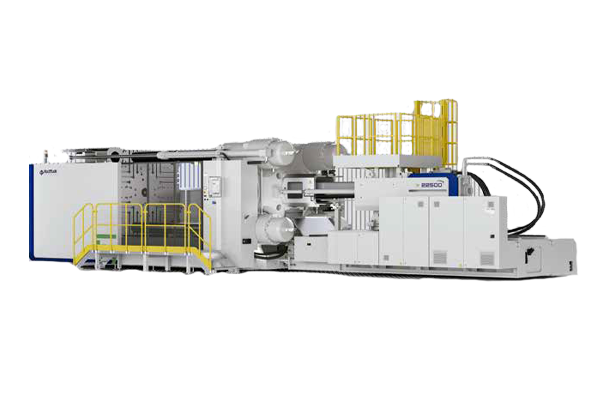

JUPITER 5 is a two-platen Haitian injection molding machine equipped with flexible open integration functions. The entire series comes standard with the "Go Factory 2.0" digital intelligent management software, providing customers with a one-stop solution for automated and digitally intelligent production.

Built on advanced drive technology, JUPITER 5 utilizes a high-performance servo motor system to achieve stable, precise, and energy-saving operation. It can also be configured to support applications requiring rapid cycles, meeting the performance requirements of a high-speed injection machine in various production scenarios.

In addition, JUPITER 5 is compatible with the latest international general interfaces as needed. Customers can freely select automation equipment and MES partners to seamlessly integrate across multi-device and multi-platform systems. With the haitian injection molding machine as the central control hub, JUPITER 5 enables open integration, ensuring efficient collaboration and flexible smart manufacturing.

Large mold space

Comprehensive upgrade of plasticizing equipment

Equipped with electric preforming

High-speed injection machine

Servo motor machine

Accurate temperature monitoring

Electric charging with 20-40% higher energy saving rate

Plastic parts products for the automotive manufacturing industry are suitable for various process technologies and application requirements and offer efficient and high-quality solutions.

In large household appliances, plastic products offer flexible, efficient and stable solutions according to product characteristics.

Plastic products with heavy mass and large projected area require large clamping force and large internal distance between tie bars; short mould transfer strokes offer effective solutions.

The large dimensions and volumes of the parts quickly shift the focus to material consumption and processing. If you want to survive in the face of tough competition, this requires well thought-out, efficient production solutions.

The JUPITER 5 is equipped with flexible open integration functions and the entire series is equipped with the digital intelligent management software "Go Factory 2.0", which can optimally meet customers' demands for automated and digitally intelligent production from a single source.

4,500 - 12,000 kN 13,000 - 88,000 kN

The JU V/W Series is optimised for highly efficient production processes with its wide plate design.

We will do our best to get back to you as soon as possible after we receive your form.